Pad printing machine technology

AddTime:2012-07-23

Editor:admin

Hit:9211

From:HC factory

A) 6 structures of pad printer:

1) Worktable. To put fixture and article, different type of pad printer with different worktable, there are mainly 4 style worktable: basic, shuttle, conveyor, disc one. The size of worktable can be customized according to the article.

2) Pad printing system.

3) Supply ink system. Open ink tray and ink cup one.

4) Scrape ink system. Ink cup system accomplishes cover ink and scrapes ink at the time, while open ink tray use doctor blade to scrape ink.

5) Control panel. There are 2 kinds of printing model, one time printing for sample test and automatic printing for mass production.

6) Ink. Solvent pad printing ink, screen printing ink and UV pad printing ink for open ink tray pad printer; usually solvent pad printing ink and screen printing ink for ink cup pad printer.

B) 5 kinds of pad printer:

1) According to printing model:manual pad printer, pneumatic pad printer and electric pad printer.

2) According to ink supply system:open ink tray pad printer and ink cup pad printer, the last one save more ink and protect environment.

3) According to print color: single colour pad printer,2 colours pad printer, 4 colors pad printer, 6 colors pad printer, 10 colors pad printer.

4) According to the worktable system: shuttle pad printer, conveyer pad printer and automatic conveyer pad printer.

5) According to the print article:flat pad printer and cylinder pad printer.

C) 4 factors about pad printing:

1) Rubber Pad

2) Plate. 3 kinds of plates are thick steel plate, thin steel plate and resin plate.

3) Pad printing ink. There are solvent ink and UV ink. You should choose ink according by the material of article, test and decide.

4) Fixture. Make jig by the shape and size of article.

5) Doctor blade.

D) How to choose pad?

1) Better to choose round or square pad if product suit.

2) If product under pressure, you’d better choose hard pad, because hard one with longer life.

3) Usually the diameter of pad is 3mm bigger than print size.

4) If print design with lots of hair line, soft pad is better.

5) Soft pad is better for uneven surface of article than hard pad.

6) The pressure depth between pad and article no more than 1/3 height of pad, or pad will be damaged easily, and designs will deformation fuzzy.

E) How to maintain pad?

1) Put pad in 5—25℃ dry and ventilated condition.

2) Please wash the new pad by alcohol before use before it got a mold release.

3) Pad may be attached dustiness when printing, please use Tina solvent clean it, to keep it clean and dry.

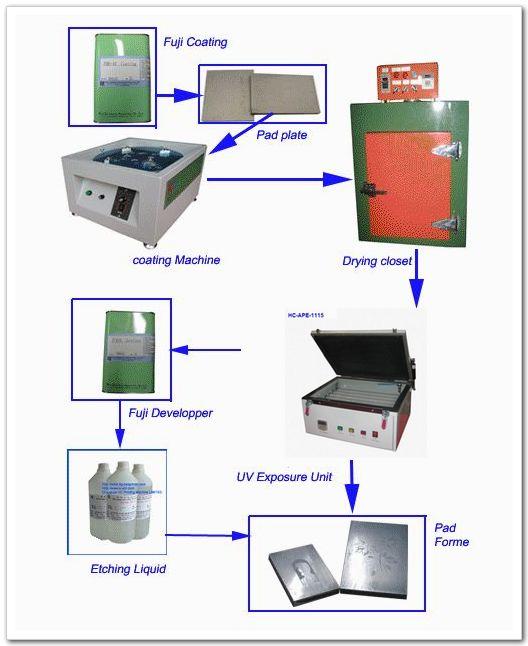

F) Nice steps to make pad plate:

1、Output film. According to the digital artworks provided by the customer, the films are output by an image setter Laser output machine. Most of films for pad printing process is positive.

2、Clean the pad plate by Tina solvent to wipe off greasy dirt.

3、Cost emulsion. Drop some Fuji emulsion on the surface of pad plate, put it in the emulsion coater rotate ensure emulsion cover on the plate evenly.

4、Dry. Put the plate which with emulsion to the drying closet for 10-15minutes, temperature is 120-150℃.

5、Exposure. Cover film on plate, then put them on the UV exposure machine, set up the time to expose 30-60 seconds; the emulsion side should close to the glass of exposure unit.

6、Develop. Drop a few Fuji developers about 10 seconds, clean the plate by water when there is image appear the plate. And dry plate by dryer at the temperature of 40-50℃.

7、Cover the non etching area by Scotch tape.

8、Etching. Use brush dip some etching liquid brush on the image size evenly. After 40 to 100 seconds there is a clean image.

9、Cleaning. Wash the etching liquid by clean water; rip out the tape, clean the left emulsion by Tina solvent.

If precision printing is required, please measure the depth of plate, standard depth should be 19-23UM.

G) 5 features of good pad printing ink:

(1)Well viscosity to the print surface.

(2)good liquidity.

(3)usually standard ink thickness is 7μm。

(4)ink gloss without change by the article surface.

(5)Dry fast, and not effect ink viscosity.

H) Doctor blade

Please note the following 3 tips when choose doctor blade:

1) Usually use 0.25mm thickness and good elasticity straight doctor blade.

2) Blade should be sharp without damage.

3) There must be some angle between doctor blade and pad plate.

I)Fixture

Fixture is specially made by the shape and size of product, clip product on worktable steady, now days it’s very popular to make jig by putty and hardner.

Pad plate making process:

|

中文版 | English

中文版 | English